This page is dedicated to how I made the birch bulkheads and rings.

Scroll down to see all page images. Photos are cropped to fit in page. To view full photo click on the image.

Dedicated to making bulkhead and rings

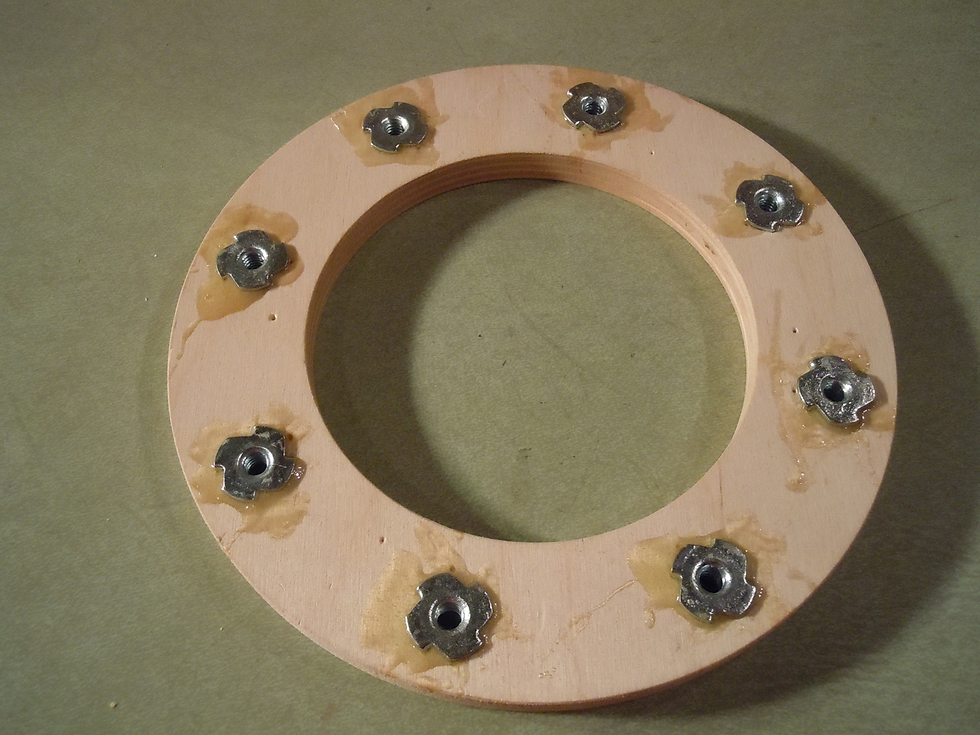

These rings will be epoxied into the Electronics bay and nose cone. The 8 equally spaced holes will have 1/4-20 T-Nuts installed. The bulkheads will be bolted to these.

All holes drilled are press fit with T-Nuts to maintain a true position of .005 on installed T-Nuts

Epoxy applied around base and under T-Nut flange then T-Nut is pounded in with Hammer.

There are two completed bulkhead attach rings. One for the nose cone and the other for the electronics bay.

The PLM bulkheads are drilled for attachment to bulkhead rings and U-bolt installation. Later the OD will be turned down in my lathe to allow a space for the epoxy Kevlar ring.

Ring is tacked in place. Next Kevlar epoxy fillet will be added to the back side of the ring to prevent low viscosity epoxy from running out of the ring to nose cone joint.

Kevlar fillet added to the back face of the ring in the nose cone. Next the joint will be filled with extreme low viscosity epoxy.

After the low viscosity epoxy is poured and cured the groove shown will be filled with epoxy and kevlar.